Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: ZK-0073

Brand: Zheke

Type: Motorcycle Engine

Material: Aluminum

Aluminum Alloying Element: ADC12

Brand: Zheke

Surface Treatment: According To Customer's Drawing Or Sample

Quality Testing Certificate: According To Customer's Deman To Quality Inspection

Weight: According To Customer's Drawing Or Sample

Packaging: Carton + Plastic film + Pallet

Productivity: 5000 Ton / Year

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 5000 Ton / Year

Certificate: ISO9001:2015

HS Code: 7616991090

Port: Guangzhou Port,Shenzhen Port,Foshan Port

Payment Type: L/C,T/T,Paypal,Western Union

Incoterm: FOB,CIF

This Motorcycle Aluminum Die Casting Cylinder is suitable for motor vehicle products

The cast aluminum cylinder can reduce the weight of the engine, save fuel, and enhance the heat dissipation of the engine, improve the engine efficiency, and have a longer life.

Zheke Motorcycle Aluminum Die Casting Cylinder high quality and low price, we can manufacture several motor vehicle parts

Zheke Mould Technology Co., Ltd founded in 2005.

Company's main business is Aluminum Die Casting Mould and aluminum die castings products R&D, design, manufacture and sale.

Customers are mainly large lighting companies, automobile parts limited and machinery manufacturing company.

The company's theoretical capacity can reach 5000 tons of aluminum/year.

Zheke Mould Company has been in the mold manufacturing industry for more than 20 years, Die casting industry over 10 years. Has many experienced technical backbone personnel.

Zheke Mould Technology Co., Ltd have four workshops, die casting material die casting machine and mould are the three major elements of die casting production.

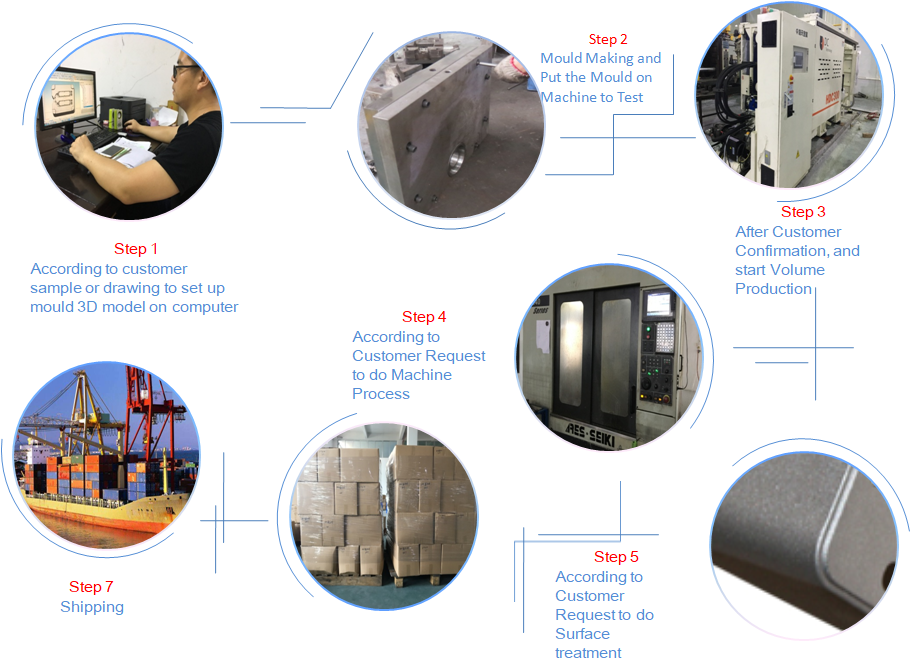

1. Aluminum Die Casting Mould Workshop. It has Radial Drilling Machines, Engine Lathe, Milling Machines, CNC EDM Wire-Cutting Machines, CNC Electric Discharge Machines, Grinding Machines for mould making. We have professional mould designer to design the mould, and we also have our own professional mould making technician team, they strictly follow mould drawing to make mould. They will carry out daily care for the moulds that customers have in our factory.

2. Die Casting Machine Workshop. We have one set hot Chamber Die Casting Machine, eight sets cold Chamber Die Casting Machines, our machine maximum can be done 800T. Before we mass production, we will text mould until customer satisfaction. We have someone to check die casting product on machine production line every day.

3. Machining Workshop. We have Drilling and Tapping Machines, CNC Lathes, CNC Machining Centre, Special Combination Machines, Hydraulic Press, Sawing Machines. We drill in strict accordance with the customer's product drawings. Machining Workshop Supervisor will conduct random sampling every day.

4. Grinding Workshop. We have Belt Polishing Machines, Pneumatic Files, Flat-Grinding Machines. We will grind and remove the edges according to the customer's requirements and product drawings. After the product has been surface treated. We have a special inspection team to carry out the final inspection of each product one by one, to ensure that each product is delivered to the customer is no problem.

1. Aluminum die casting product advantage:

1) Light Weight;

2) Retain high dimensional stability thin walls and complex shapes;

3) Corrosion resistant;

4) Good mechanical properties;

5) Has the bearing capacity in as wide range of temperatures;

6) High thermal and electrical conductivity;

7) Finishing has smooth surface.

2. Our company advantage:

1) We have good sales team and technical team;

2) Product quality assurance;

3) We give you from pre-sales to after-sale services;

4) We provide die-casting aluminum service;

5) We making worth by heart;

Product Categories : Automobile Aluminum Die Casting Parts > Automotive Motorcycle Parts

Home > Products > Automobile Aluminum Die Casting Parts > Automotive Motorcycle Parts > Motorcycle Aluminum Die Casting Cylinder

Send Inquiry

Mr. Atlas Chen

Tel:86-0757-85688170

Fax:86-0757-85107266

Mobile Phone:+8618676585274

Email:atlaschen@zkdiecasting.com

Address:Boai&Hongling rd, Shishan Town,Nanhai, Foshan, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.